Leading Manufacturer of Membrane Switches

WHAT UTC DO

UT serves as your comprehensive supplier for tailored components, molded parts, and assemblies, specializing in customized operating units. Additionally, our product range includes standard components like spring contacts and micro buttons to complement our offerings.

WHAT UTC OFFER

UT supports our clients from the initial concept to mass production, offering a full-service experience:

From development and design to series manufacturing and logistical management. Ultimately, you receive the finished product ready for use.

WHAT UTC BENEFIT YOU

You gain from our extensive expertise and wide-ranging services.

Moreover, our in-house manufacturing capabilities and exclusive supplier network provide you with significant competitive advantages.

Is your company involved in developing Human Machine Interfaces? If that’s the case, a quick conversation with our experts at UT could provide the ideal solution to meet your requirements. Whether it’s for your membrane switch’s primary purpose or something else, UT offers complete customization, ensuring top-notch graphics and engineering features.

READ MORETypes of Products

Why Choose UTC as Membrane Switch Supplier

Superior Quality and Durability

We use premium materials and cutting-edge technology to produce membrane switches that are not only highly responsive and reliable but also built to withstand harsh environments and extensive usage.

Customizable Design Solutions

Our team specializes in creating bespoke membrane switch solutions tailored to meet your specific requirements, ensuring seamless integration with your products and enhancing their functionality and aesthetic appeal.

Fast Turnaround & Competitive Price

With efficient manufacturing processes and a commitment to affordability, we deliver high-quality membrane switches quickly and at a price point that supports your budget, without compromising on quality.

Exceptional Customer Support

We pride ourselves on our comprehensive customer service, offering expert guidance from design to delivery and ensuring that every client receives personalized attention to meet their unique needs and expectations.

Get Your Custom Membrane Switch

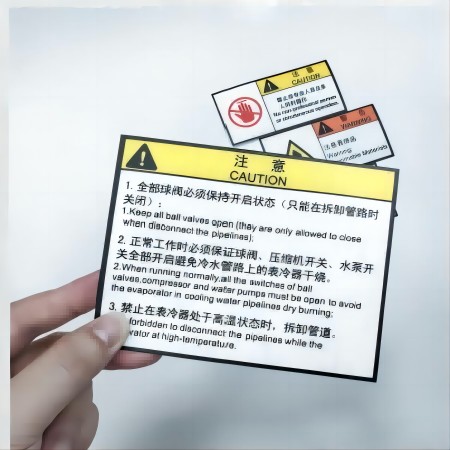

Union Tech Circuit is a trusted electronics print manufacturer with years of experience in creating high-quality electronics print solutions for various industries. It specializes in manufacturing high-quality custom membrane switches, print labels and silicone rubbers to cover various needs of customers. Here are your custom selections:

Get A free quoteMembrane Switch Technology

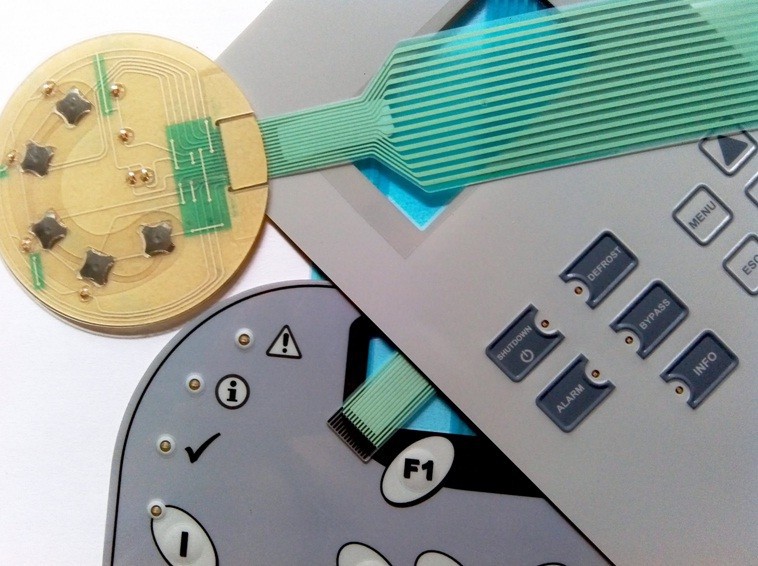

UTC’s membrane switch technology combines thin, flexible layers with advanced printing techniques to create durable, reliable interfaces. Ideal for various applications, it offers tactile feedback, customizable designs, and seamless integration, ensuring superior performance and user satisfaction.

Sleek and Durable Interface Solution

Membrane switch technology offers a sleek, durable interface ideal for electronics, blending precision with cost-efficiency for diverse applications.

Tactile Feedback and Durability

Designed with layers of flexible materials, membrane switches provide tactile feedback and are resistant to moisture and contaminants, ensuring reliability in challenging environments.

Customizable and Ergonomic Designs

These switches integrate seamlessly into electronic devices, offering customizable graphics, backlighting options, and ergonomic designs tailored to user interface requirements.

Versatile Applications Across Industries

Known for their low-profile design and ease of integration, membrane switches are crucial in industries such as medical devices, consumer electronics, and industrial controls.

Our Membrane Switch Factory

After-Sales Support of Custom Membrane Switch

After-sales support for membrane switches typically involves several key aspects to ensure customer satisfaction and continued functionality of the product. Here are some common components of after-sales support for membrane switches:

- Technical Support: Providing technical assistance to troubleshoot any issues customers may encounter with the membrane switch. This could involve guiding them through diagnostics, suggesting solutions, or offering repair services if necessary.

- Warranty Services: Ensuring that the membrane switch is covered under warranty, if applicable, and handling any warranty claims promptly. This may involve repairing or replacing defective switches according to the terms of the warranty.

- Repair and Replacement: Offering repair services for damaged or malfunctioning membrane switches beyond the warranty period. This could include replacing worn-out components, fixing electrical issues, or reprogramming the switch if needed.

- Customer Training: Providing training materials or sessions to educate customers on the proper use, maintenance, and care of the membrane switch. This helps reduce the likelihood of issues arising due to improper handling.

- Feedback and Improvement: Gathering feedback from customers about their experiences with the membrane switch and using this information to improve future products or services. Addressing common issues reported by customers can lead to better product design and customer satisfaction.

- Availability of Spare Parts: Ensuring that spare parts for the membrane switch are readily available for purchase or replacement. This facilitates quick repairs and minimizes downtime for customers.

- Continuous Communication: Maintaining open lines of communication with customers to address any questions or concerns they may have about the membrane switch, even after the initial sale. This can be done through various channels such as phone support, email correspondence, or online chat.

What Our Other Customers Say About Us

Electronics Print FAQs

A membrane switch is a low-profile, flexible switch device that uses printed electronic circuits to operate a device or control panel.

It consists of multiple layers: a graphic overlay (often with printed design and labels), a flexible printed circuit (PCB) layer with conductive traces, a spacer layer, and a rear adhesive layer. Pressing on the graphic overlay closes the circuit, activating the switch.

Membrane switches offer several advantages: they are durable, easy to clean, resistant to moisture and dust ingress, customizable in terms of design and tactile feedback, and cost-effective for mass production.

Customization options include graphic design (colors, logos, labels), tactile feedback (embossing, metal domes), backlighting (LEDs for illumination), and integration of additional features like shielding or sealing against environmental factors.

Membrane switches are used across various industries, including medical devices, industrial equipment, consumer electronics, automotive applications, and appliances, due to their reliability and customization capabilities.