Din pålidelige producent af trykt elektronik

Udforsk banebrydende trykte elektronikløsninger med UTC. Som en pålidelig producent har vi specialiseret os i at levere tilpassede trykte elektroniske komponenter, herunder membranafbrydere, silikonegummitastaturer og trykte etiketter. Vores avancerede produktionskapacitet sikrer præcision og pålidelighed og opfylder de unikke krav i brancher som bilindustrien, medicinsk udstyr og forbrugerelektronik. Støttet af innovation og en forpligtelse til kvalitet giver vi vores kunder mulighed for problemfri integration af trykt elektronik, hvilket forbedrer produktets ydeevne og funktionalitet. Opdag, hvordan UTC kan løfte dine projekter med vores ekspertise og dedikation til excellence

Send forespørgselTyper af trykt elektronik

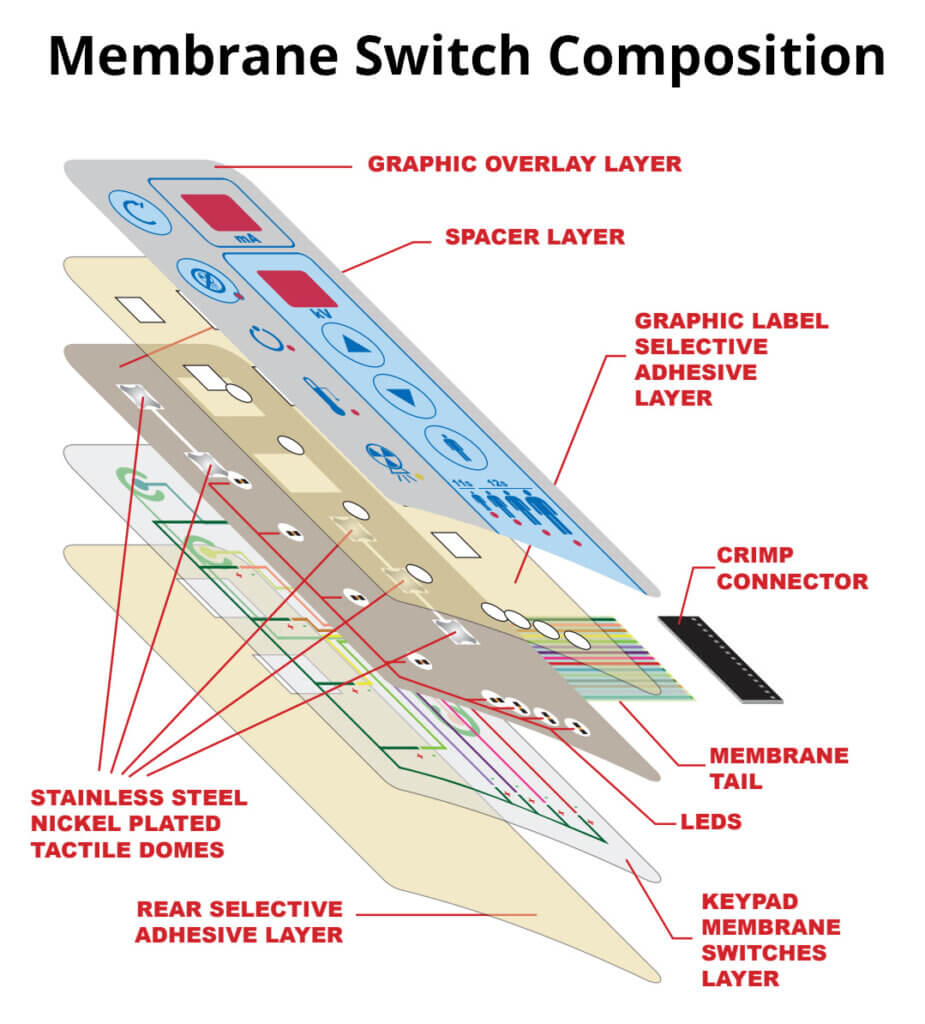

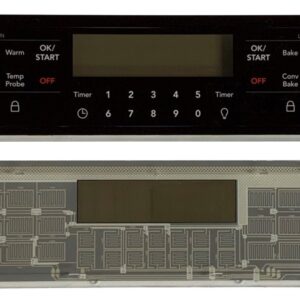

Membranafbrydere

Oplev alsidige og pålidelige membranafbrydere hos UTC. Vores specialdesignede membranafbrydere er perfekte til forskellige anvendelser og tilbyder problemfri integration, holdbarhed og præcis funktionalitet. Udforsk vores sortiment, der er skræddersyet til at opfylde dine specifikke behov og løfte dit produkts brugergrænseflade.

Få et gratis tilbudSilikone-gummi

Løft brugeroplevelsen med silikonegummitastaturer fra UTC. Vores tastaturer, der kan tilpasses, kombinerer taktil feedback med holdbarhed og er ideelle til forskellige anvendelser. Udforsk vores udvalg af silikonegummitastaturer, der er designet til at forbedre brugervenligheden og pålideligheden i dine produkter.

Få et gratis tilbudUdskriv etiketter

Oplev præcision og kvalitet med printlabels fra UTC. Vores etiketter, der kan tilpasses, er fremstillet med avancerede trykteknikker for at sikre klarhed og holdbarhed. Uanset om det er til branding, compliance eller identifikation, så udforsk vores alsidige printlabels, der er skræddersyet til at opfylde dine nøjagtige specifikationer.

Funktioner, der gør vores trykte elektronik til industrien unik

Ekspertise og erfaring

Med 20 års brancheekspertise leverer vores team ekspertrådgivning og optimerede løsninger.

At fremhæve erfaring kan opbygge tillid og troværdighed hos potentielle kunder.

Fokus på innovation og R&D

Vores engagement i kontinuerlig innovation og løbende F&U-indsats holder os på forkant med udviklingen inden for trykt elektronik.

At fremhæve innovation kan appellere til brancher, der leder efter partnere, der driver den teknologiske udvikling.

Global rækkevidde og support

Med et globalt fodaftryk leverer vi pålidelig support og rettidig levering til kunder over hele verden.

Hvis det er relevant, kan fremvisning af globale kompetencer appellere til multinationale virksomheder.

Kundernes succeshistorier

Se, hvordan førende industrier har nydt godt af vores skræddersyede løsninger til trykt elektronik.

At inkludere casestudier eller udtalelser kan give socialt bevis og skabe tillid hos potentielle kunder.

Fremstillingsprocessen for trykt elektronik

Forberedelse af substrat: Vælg og rengør fleksible materialer som PET eller papir for at opnå optimal vedhæftning af blæk og kompatibilitet med trykteknikker.

Udskrivning: Brug metoder som inkjet eller serigrafi til at afsætte ledende, halvledende og isolerende blæk på underlaget, så der dannes elektroniske mønstre.

Hærdning: Påfør varme eller UV-hærdning for at størkne farverne og forbedre deres ledningsevne og holdbarhed på underlaget.

Integration af komponenter: Placer elektroniske komponenter som sensorer eller lysdioder på det trykte substrat og sørg for præcis justering og tilslutning.

Testning og emballering: Udfør strenge elektriske og holdbarhedstests for at kontrollere funktionaliteten. Til sidst pakkes den trykte elektronik forsvarligt ind til distribution og brug.

Anvendelsestilfælde for silikoneprodukter

FÅ ET GRATIS TILBUDEr du klar til at få de perfekte trykte elektroniske produkter?

Kontakt os for at få en gratis konsultation

Ofte stillede spørgsmål om trykt elektronik

Trykt elektronik refererer til elektroniske enheder eller komponenter, der er fremstillet ved hjælp af trykteknikker, typisk på fleksible underlag som plast eller papir.

Trykt elektronik giver fordele som fleksibilitet, lav vægt, billig produktion, skalerbarhed til applikationer med store områder og potentiale for integration i forskellige overflader og former.

Trykt elektronik finder anvendelse i forskellige brancher, herunder bærbar teknologi, fleksible skærme, smart emballage, sensorer til IoT-enheder, medicinsk diagnostik og meget mere.

Trykt elektronik kan opnå en pålidelighed, der kan sammenlignes med traditionel elektronik, takket være fremskridt inden for materialer, trykprocesser og strenge testprotokoller, der sikrer funktionalitet og holdbarhed.

Ja, trykt elektronik kan bidrage til bæredygtighedsindsatsen ved at reducere materialespild og energiforbrug i produktionen og muliggøre innovative, miljøvenlige anvendelser.

Ja, trykt elektronik er skalerbar til masseproduktion på grund af deres kompatibilitet med højhastighedsprintprocesser og potentiale for integration i automatiserede produktionslinjer.