Ihr zuverlässiger Leiterplattenhersteller

Entdecken Sie hochmoderne Lösungen für gedruckte Elektronik mit UTC. Als vertrauenswürdiger Hersteller sind wir auf die Lieferung kundenspezifischer gedruckter elektronischer Komponenten spezialisiert, darunter Folientastaturen, Silikonkautschuk-Tastaturen und Drucketiketten. Unsere fortschrittlichen Fertigungskapazitäten gewährleisten Präzision und Zuverlässigkeit und erfüllen die besonderen Anforderungen von Branchen wie Automobil, Medizintechnik und Unterhaltungselektronik. Gestützt auf Innovation und ein Bekenntnis zur Qualität, ermöglichen wir unseren Kunden die nahtlose Integration von gedruckter Elektronik, wodurch die Produktleistung und -funktionalität verbessert werden. Entdecken Sie, wie UTC Ihre Projekte mit unserem Fachwissen und unserem Engagement für Exzellenz verbessern kann

Anfrage sendenArten von gedruckter Elektronik

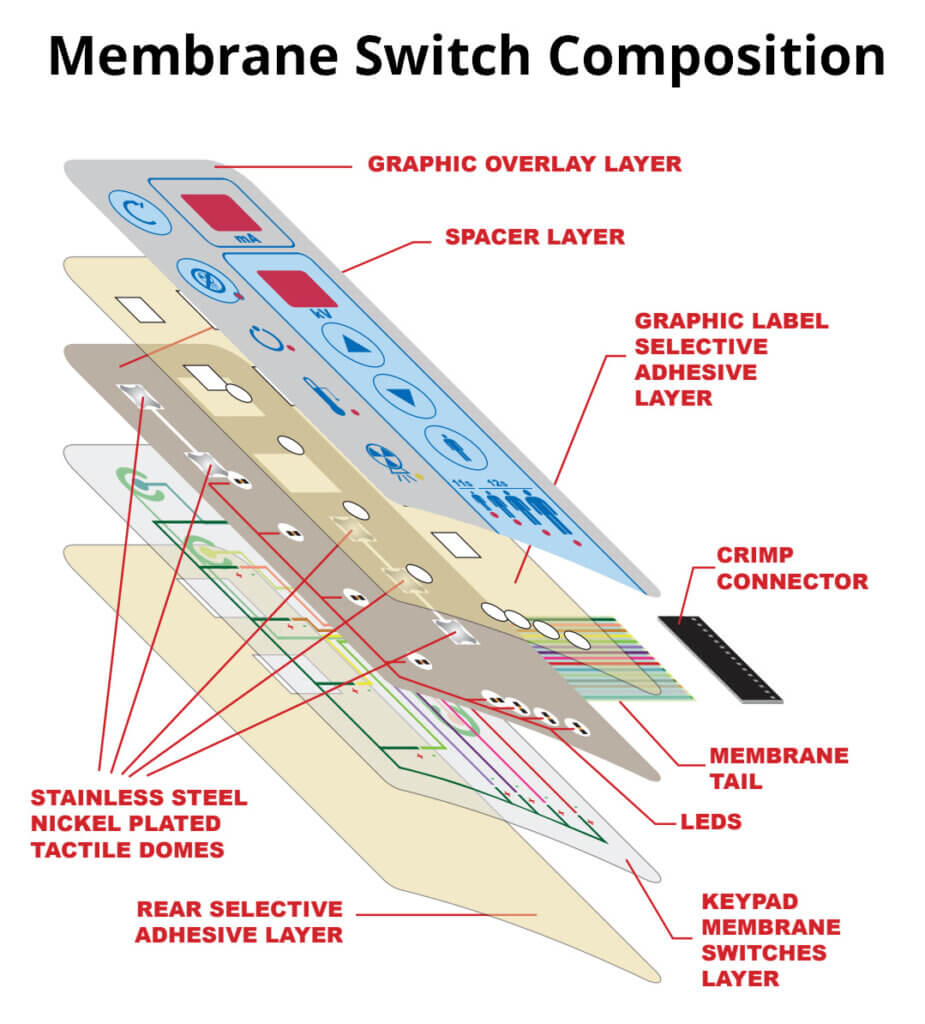

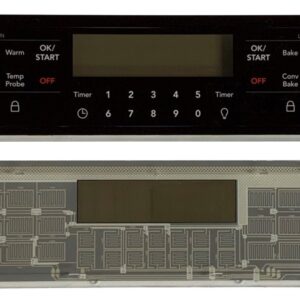

Membranschalter

Entdecken Sie vielseitige und zuverlässige Folientastaturen bei UTC. Unsere kundenspezifischen Folientastaturen sind perfekt für vielfältige Anwendungen und bieten nahtlose Integration, Haltbarkeit und präzise Funktionalität. Entdecken Sie unser Sortiment, das auf Ihre spezifischen Bedürfnisse zugeschnitten ist und die Benutzeroberfläche Ihres Produkts verbessert.

Holen Sie sich ein kostenloses AngebotSilikongummi

Verbessern Sie die Benutzererfahrung mit Silikonkautschuk-Tastaturen von UTC. Unsere anpassbaren Tastaturen kombinieren taktiles Feedback mit Haltbarkeit und sind ideal für verschiedene Anwendungen. Entdecken Sie unser Sortiment an Silikonkautschuk-Tastaturen, die entwickelt wurden, um die Benutzerfreundlichkeit und Zuverlässigkeit Ihrer Produkte zu verbessern.

Holen Sie sich ein kostenloses AngebotDrucketiketten

Entdecken Sie Präzision und Qualität mit Drucketiketten von UTC. Unsere anpassbaren Etiketten werden mit fortschrittlichen Drucktechniken hergestellt, um Klarheit und Haltbarkeit zu gewährleisten. Ob für Branding, Compliance oder Identifizierung, entdecken Sie unsere vielseitigen Drucketiketten, die auf Ihre genauen Spezifikationen zugeschnitten sind.

Funktionen, die unsere gedruckte Elektronik für die Industrie einzigartig machen

Expertise und Erfahrung

Mit 20 Jahren Branchenerfahrung bietet unser Team kompetente Beratung und optimierte Lösungen.

Das Hervorheben von Erfahrung kann Vertrauen und Glaubwürdigkeit bei potenziellen Kunden aufbauen.

Innovation und F&E-Fokus

Unser Engagement für kontinuierliche Innovation und laufende F&E-Bemühungen hält uns an der Spitze der Fortschritte in der gedruckten Elektronik.

Das Hervorheben von Innovationen kann Branchen ansprechen, die nach Partnern suchen, die den technologischen Fortschritt vorantreiben.

Globale Reichweite und Support

Mit einer globalen Präsenz bieten wir zuverlässigen Support und pünktliche Lieferung an Kunden weltweit.

Falls zutreffend, kann die Präsentation globaler Fähigkeiten multinationale Unternehmen ansprechen.

Erfolgsgeschichten von Kunden

Entdecken Sie, wie führende Branchen von unseren kundenspezifischen Lösungen für gedruckte Elektronik profitiert haben.

Das Hinzufügen von Fallstudien oder Erfahrungsberichten kann einen sozialen Beweis liefern und das Vertrauen potenzieller Kunden stärken.

Herstellungsprozess von gedruckter Elektronik

Substratvorbereitung: Wählen und reinigen Sie flexible Materialien wie PET oder Papier für optimale Tintenhaftung und Kompatibilität mit Drucktechniken.

Drucken: Verwenden Sie Methoden wie Tintenstrahl- oder Siebdruck, um leitfähige, halbleitfähige und isolierende Tinten auf das Substrat aufzutragen und so elektronische Muster zu bilden.

Aushärten: Tragen Sie Wärme- oder UV-Härtung auf, um die Tinten zu verfestigen und ihre Leitfähigkeit und Haltbarkeit auf dem Substrat zu verbessern.

Komponentenintegration: Platzieren Sie elektronische Komponenten wie Sensoren oder LEDs auf dem gedruckten Substrat und stellen Sie eine präzise Ausrichtung und Verbindung sicher.

Testen und Verpacken: Führen Sie strenge elektrische und Haltbarkeitstests durch, um die Funktionalität zu überprüfen. Verpacken Sie die gedruckte Elektronik abschließend sicher für den Vertrieb und die Verwendung.

Anwendungsfälle für Silikonprodukte

KOSTENLOSES ANGEBOT EINHOLENSind Sie bereit, die perfekten gedruckten elektronischen Produkte zu erhalten?

Kontaktieren Sie uns für eine kostenlose Beratung

FAQs zu gedruckter Elektronik

Gedruckte Elektronik bezieht sich auf elektronische Geräte oder Komponenten, die mithilfe von Drucktechniken hergestellt werden, typischerweise auf flexiblen Substraten wie Kunststoff oder Papier.

Gedruckte Elektronik bietet Vorteile wie Flexibilität, geringes Gewicht, kostengünstige Produktion, Skalierbarkeit für großflächige Anwendungen und das Potenzial zur Integration in verschiedene Oberflächen und Formen.

Gedruckte Elektronik findet Anwendung in verschiedenen Branchen, darunter tragbare Technologie, flexible Displays, intelligente Verpackungen, Sensoren für IoT-Geräte, medizinische Diagnostik und mehr.

Gedruckte Elektronik kann durch Fortschritte bei Materialien, Druckprozessen und strengen Testprotokollen, die Funktionalität und Haltbarkeit gewährleisten, eine mit herkömmlicher Elektronik vergleichbare Zuverlässigkeit erreichen.

Ja, gedruckte Elektronik kann zu Nachhaltigkeitsbemühungen beitragen, indem sie Materialverschwendung und Energieverbrauch in der Produktion reduziert und innovative, umweltfreundliche Anwendungen ermöglicht.

Ja, gedruckte Elektronik ist aufgrund ihrer Kompatibilität mit Hochgeschwindigkeitsdruckprozessen und dem Potenzial zur Integration in automatisierte Fertigungslinien für die Massenproduktion skalierbar.