信頼できるプリンテッドエレクトロニクスメーカー

UTCで最先端のプリンテッドエレクトロニクスソリューションをご検討ください。UTCは信頼できるメーカーとして、メンブレンスイッチ、シリコンラバーキーパッド、プリントラベルなど、カスタマイズされたプリント電子部品を専門に提供しています。当社の高度な製造能力は、自動車、医療機器、家電製品などの業界特有の要件を満たす精度と信頼性を保証します。技術革新と品質へのこだわりに支えられ、プリンテッドエレクトロニクスのシームレスな統合によりお客様に力を与え、製品の性能と機能性を高めます。UTCの専門知識と卓越性への献身が、お客様のプロジェクトをどのように向上させるかをご覧ください。

お問い合わせを送信プリンテッドエレクトロニクスの種類

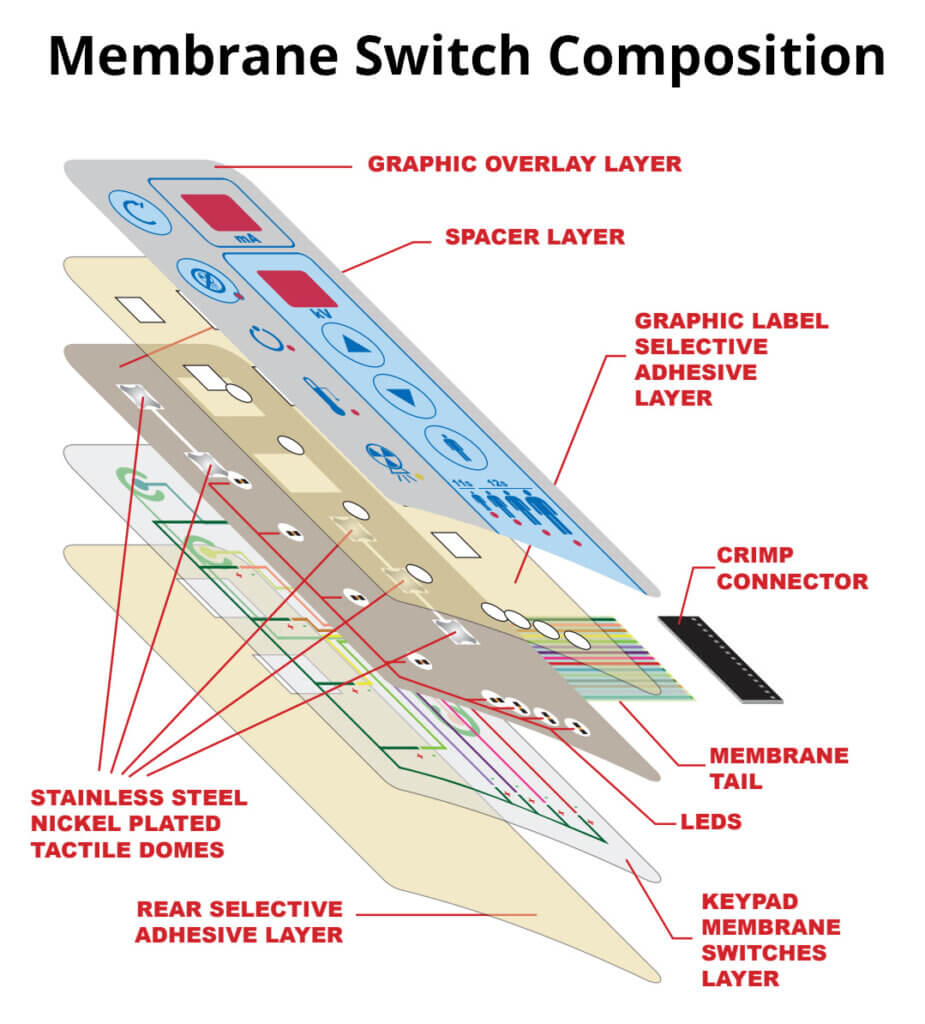

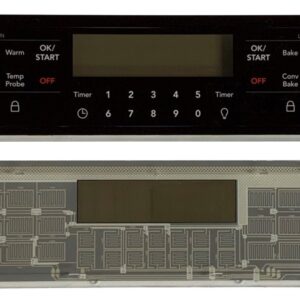

メンブレン・スイッチ

UTCの汎用性と信頼性の高いメンブレンスイッチをご覧ください。多様なアプリケーションに最適なカスタム設計のメンブレンスイッチは、シームレスな統合、耐久性、正確な機能を提供します。お客様のニーズに合わせてカスタマイズされた製品群をご覧いただき、製品のユーザーインターフェースを向上させてください。

無料お見積もりシリコーンゴム

UTCのシリコンラバーキーパッドでユーザーエクスペリエンスを向上させましょう。当社のカスタマイズ可能なキーパッドは、触覚フィードバックと耐久性を兼ね備えており、さまざまな用途に最適です。製品の使いやすさと信頼性を高めるために設計されたシリコンラバーキーパッドのラインナップをご覧ください。

無料お見積もりラベル印刷

UTCのプリントラベルで精度と品質を実感してください。UTCのカスタマイズ可能なラベルは、鮮明さと耐久性を保証する高度な印刷技術で作られています。ブランディング、コンプライアンス、識別など、お客様の仕様に合わせた多彩なラベルをご用意しています。

産業用プリンテッドエレクトロニクスの特徴

専門知識と経験

20年にわたる業界の専門知識を持つ私たちのチームは、専門的なコンサルティングと最適なソリューションを提供します。

経験を強調することで、潜在的な顧客からの信頼と信用を築くことができる。

イノベーションと研究開発

継続的な技術革新と継続的な研究開発への取り組みにより、当社はプリンテッドエレクトロニクスの進歩の最前線に立ち続けています。

技術革新を強調することで、技術進歩を推進するパートナーを探している業界にアピールすることができる。

グローバル・リーチとサポート

グローバルな事業展開により、世界中のお客様に信頼性の高いサポートとタイムリーな納品を提供しています。

該当する場合は、グローバルな能力をアピールすることで、多国籍企業にアピールすることができる。

お客様の成功事例

当社のカスタマイズされたプリンテッドエレクトロニクス・ソリューションが、主要産業でどのように役立っているかをご覧ください。

ケーススタディや証言を含めることで、社会的な証拠を提供し、潜在的な顧客に自信を抱かせることができる。

プリンテッドエレクトロニクスの製造工程

基板の準備: PETや紙のような柔軟性のある素材を選択し、クリーニングすることで、インクの密着性と印刷技術との適合性を最適化する。

印刷: インクジェットやスクリーン印刷のような方法で、導電性、半導体性、絶縁性のインクを基板に付着させ、電子パターンを形成する。

養生: 熱またはUV硬化を施してインクを固化させ、基材上での導電性と耐久性を向上させる。

コンポーネントの統合: センサーやLEDなどの電子部品をプリント基板上に配置し、正確な位置合わせと接続を確保する。

試験と包装: 機能性を確認するために、厳しい電気的テストと耐久性テストを実施する。最後に、プリント・エレクトロニクスを流通・使用できるように安全に梱包します。

シリコーン製品 用途例

無料お見積もりプリンテッドエレクトロニクスFAQ

プリンテッドエレクトロニクスとは、印刷技術を用いて製造される電子機器や電子部品のことで、一般的にはプラスチックや紙などの柔軟な基材上に製造される。

プリンテッドエレクトロニクスは、柔軟性、軽量、低コスト生産、大面積アプリケーションのための拡張性、さまざまな表面や形状への統合の可能性などの利点を提供する。

プリンテッドエレクトロニクスは、ウェアラブル技術、フレキシブルディスプレイ、スマートパッケージング、IoT機器用センサー、医療診断など、さまざまな産業で応用されている。

プリンテッドエレクトロニクスは、材料、印刷プロセス、機能性と耐久性を保証する厳格な試験プロトコルの進歩により、従来のエレクトロニクスに匹敵する信頼性を達成することができる。

そう、プリンテッドエレクトロニクスは、材料廃棄物や生産におけるエネルギー消費を削減し、環境に優しい革新的なアプリケーションを可能にすることで、持続可能な取り組みに貢献することができる。

そう、プリンテッドエレクトロニクスは、高速印刷プロセスとの互換性や、自動化された製造ラインへの統合の可能性から、大量生産への拡張性がある。