In-Mold Electronics (IME): A Revolutionary Technology

Key Benefits of In-Mold Electronics:

- Reduced Assembly Costs: By integrating electronic components directly into the plastic part, IME eliminates the need for separate assembly steps, significantly reducing manufacturing costs.

- Improved Durability: IME creates a strong bond between the electronic components and the plastic part, enhancing durability and resistance to environmental factors.

- Smaller Form Factor: IME allows for the creation of thinner and more compact electronic devices, making them more portable and aesthetically pleasing.

- Enhanced Aesthetics: IME can be used to create seamless and visually appealing designs, integrating electronic components seamlessly into the overall product appearance.

- Improved Reliability: By eliminating external connections and assembly steps, IME can enhance the reliability and longevity of electronic products.

Applications of In-Mold Electronics:

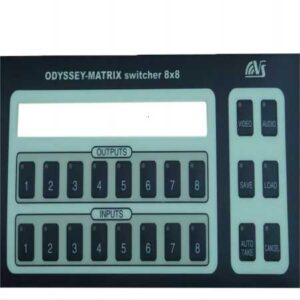

- Consumer Electronics: Keyboards, remote controls, automotive dashboards, and wearable devices.

- Medical Devices: Diagnostic equipment, patient monitoring systems, and implantable devices.

- Automotive: Control panels, instrument clusters, and door panels.

- Industrial Automation: Control panels, sensors, and other automation components.