Vaš zanesljiv proizvajalec tiskane elektronike

Raziščite vrhunske rešitve tiskane elektronike z UTC. Kot zaupanja vreden proizvajalec smo specializirani za dobavo prilagojenih tiskanih elektronskih komponent, vključno z membranskimi stikali, silikonskimi gumijastimi tipkovnicami in tiskanimi etiketami. Naše napredne proizvodne zmogljivosti zagotavljajo natančnost in zanesljivost, ki izpolnjujejo edinstvene zahteve panog, kot so avtomobilska industrija, medicinski pripomočki in potrošniška elektronika. Podprti z inovativnostjo in zavezanostjo kakovosti, našim strankam omogočamo brezhibno integracijo tiskane elektronike, kar izboljšuje učinkovitost in funkcionalnost izdelkov. Odkrijte, kako lahko UTC izboljša vaše projekte z našim strokovnim znanjem in predanostjo odličnosti

Pošlji povpraševanjeVrste tiskane elektronike

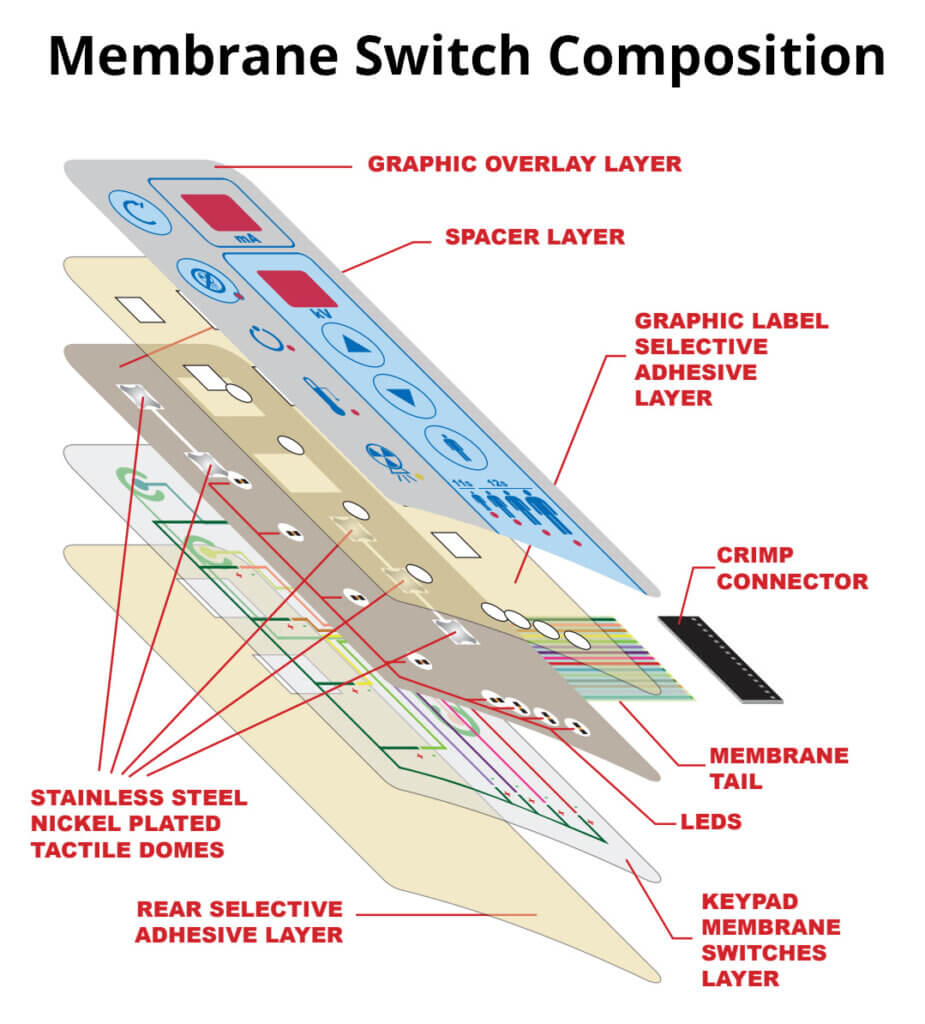

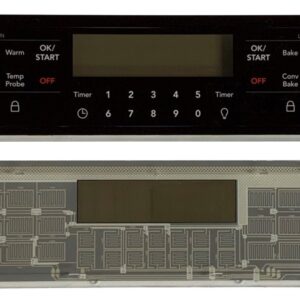

Membranska stikala

Odkrijte vsestranska in zanesljiva membranska stikala pri UTC. Naša po meri zasnovana membranska stikala, ki so popolna za različne aplikacije, ponujajo brezhibno integracijo, vzdržljivost in natančno funkcionalnost. Raziščite našo ponudbo, prilagojeno vašim specifičnim potrebam, in izboljšajte uporabniški vmesnik vašega izdelka.

Pridobite brezplačno ponudboSilikonska guma

Izboljšajte uporabniško izkušnjo s silikonskimi gumijastimi tipkovnicami podjetja UTC. Naše prilagodljive tipkovnice združujejo taktilno povratno informacijo z vzdržljivostjo, idealne za različne aplikacije. Raziščite našo ponudbo silikonskih gumijastih tipkovnic, zasnovanih za izboljšanje uporabnosti in zanesljivosti vaših izdelkov.

Pridobite brezplačno ponudboTiskane etikete

Odkrijte natančnost in kakovost s tiskanimi etiketami podjetja UTC. Naše prilagodljive etikete so izdelane z naprednimi tehnikami tiskanja, ki zagotavljajo jasnost in vzdržljivost. Ne glede na to, ali gre za blagovno znamko, skladnost ali identifikacijo, raziščite naše vsestranske tiskane etikete, prilagojene vašim natančnim specifikacijam.

Lastnosti, zaradi katerih je naša tiskana elektronika za industrijo edinstvena

Strokovno znanje in izkušnje

Z 20-letnimi strokovnimi izkušnjami v industriji naša ekipa zagotavlja strokovno svetovanje in optimizirane rešitve.

Poudarjanje izkušenj lahko zgradi zaupanje in verodostojnost pri potencialnih strankah.

Inovacije in osredotočenost na raziskave in razvoj

Naša zavezanost nenehnim inovacijam in tekočim prizadevanjem za raziskave in razvoj nas ohranja v ospredju napredka tiskane elektronike.

Poudarjanje inovacij je lahko privlačno za industrije, ki iščejo partnerje, ki spodbujajo tehnološki napredek.

Globalni doseg in podpora

Z globalno prisotnostjo zagotavljamo zanesljivo podporo in pravočasno dostavo strankam po vsem svetu.

Če je primerno, lahko predstavitev globalnih zmogljivosti pritegne mednarodna podjetja.

Zgodbe o uspehu strank

Raziščite, kako so vodilne industrije imele koristi od naših prilagojenih rešitev tiskane elektronike.

Vključitev študij primerov ali pričevanj lahko zagotovi družbeni dokaz in vzbudi zaupanje pri potencialnih strankah.

Proizvodni proces tiskane elektronike

Priprava podlage: Izberite in očistite prožne materiale, kot sta PET ali papir, za optimalen oprijem črnila in združljivost s tehnikami tiskanja.

Tiskanje: Uporabite metode, kot sta brizgalno ali sitotisk, za nanašanje prevodnih, polprevodnih in izolacijskih črnila na podlago, ki tvorijo elektronske vzorce.

Sušenje: Uporabite toplotno ali UV sušenje, da strdite črnila, s čimer izboljšate njihovo prevodnost in vzdržljivost na podlagi.

Integracija komponent: Postavite elektronske komponente, kot so senzorji ali LED diode, na tiskano podlago, pri čemer zagotovite natančno poravnavo in povezavo.

Testiranje in pakiranje: Izvedite stroge električne in preizkuse vzdržljivosti, da preverite funkcionalnost. Na koncu varno zapakirajte tiskano elektroniko za distribucijo in uporabo.

Primeri uporabe silikonskih izdelkov

PRIDOBITE BREZPLAČNO PONUDBOSte pripravljeni dobiti popolne tiskane elektronske izdelke?

Pišite nam za brezplačno posvetovanje

Pogosta vprašanja o tiskani elektroniki

Tiskana elektronika se nanaša na elektronske naprave ali komponente, ki so izdelane s tehnikami tiskanja, običajno na prožnih podlagah, kot sta plastika ali papir.

Tiskana elektronika ponuja prednosti, kot so prožnost, majhna teža, nizki stroški proizvodnje, razširljivost za aplikacije na velikih površinah in potencial za integracijo v različne površine in oblike.

Tiskana elektronika najde uporabo v različnih panogah, vključno z nosljivo tehnologijo, prožnimi zasloni, pametno embalažo, senzorji za naprave IoT, medicinsko diagnostiko in še več.

Tiskana elektronika lahko doseže zanesljivost, primerljivo s tradicionalno elektroniko, z napredkom v materialih, postopkih tiskanja in strogih protokolih testiranja, ki zagotavljajo funkcionalnost in vzdržljivost.

Da, tiskana elektronika lahko prispeva k prizadevanjem za trajnost z zmanjšanjem odpadkov materiala, porabe energije pri proizvodnji in omogočanjem inovativnih okolju prijaznih aplikacij.

Da, tiskana elektronika je razširljiva za množično proizvodnjo zaradi njene združljivosti s hitrimi postopki tiskanja in potenciala za integracijo v avtomatizirane proizvodne linije.